Way of Decrease TCO – the Advantage of U Shaped Holes

Considering the abrasion resistant character of AlSiC material, it is pretty hard to drill a hole on AlSiC composite material. With electric spark, one hole might take half a hour. Laser only applies to thin plate. Inside the industry, there are two ways to deal with holes: one is that, leave the place where hole locates with only aluminum to facilitate drilling afterward; the other is to use U shaped hole to replace round hole. Comparatively, U shaped hole could be build with infiltration process, saving manufacturing cost and reducing lead time. So, U shaped hole is always recommended.

Considering the abrasion resistant character of AlSiC material, it is pretty hard to drill a hole on AlSiC composite material. With electric spark, one hole might take half a hour. Laser only applies to thin plate. Inside the industry, there are two ways to deal with holes: one is that, leave the place where hole locates with only aluminum to facilitate drilling afterward; the other is to use U shaped hole to replace round hole. Comparatively, U shaped hole could be build with infiltration process, saving manufacturing cost and reducing lead time. So, U shaped hole is always recommended.

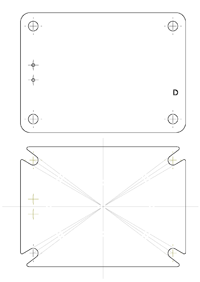

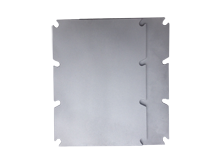

The principle of designing U shaped hole is illustrated in Fig. (upper shows the round hole product, lower shows the same product  changed to U shaped holes), that is, the opening direction of U shape hole is supposed to be in the same line that product shrink along while cooling after casting. This method designed products, are easy to be unloaded and the mold is also to be protected to increase mold re-use times. The cost of mold is main part of product cost, increase mold re-use times is to decrease the total cost of ownership.

changed to U shaped holes), that is, the opening direction of U shape hole is supposed to be in the same line that product shrink along while cooling after casting. This method designed products, are easy to be unloaded and the mold is also to be protected to increase mold re-use times. The cost of mold is main part of product cost, increase mold re-use times is to decrease the total cost of ownership.

In addition, better leave a draft angel of 5°along the unloading direction.

back to AlSiC introduction back to Product Design Guide last one